As far as packaging is concerned, the choice of the size of heat-seal paper will be critical in taking care of the product protection and efficiency of the operation. The correct size will ensure that the quality of your products does not drop and that you minimize wastage and shorten the sealing process. In packaging both delicate items and bulk products, sizing also plays a very important role in getting your packaging solutions to work like clockwork. With this guide, I will guide you in some of the factors that you need to know before making a decision on heat seal paper size, so you have a good head of the situation. We discuss all of this, including the size of your products, to the kind of sealing machine that you prefer.

Learn About Your Product Dimensions First

Determine the full size of products you would like to package before placing a Heat Seal Paper order. Consider the length, width, and thickness in order not to make any unwanted cuts or ill-fits. Note that you need to use paper that is a little bit bigger than your product in order to be able to seal it out without causing wrinkles or tearing on the paper. With the odd-shaped product, custom fit is advised in order to fit the product adequately and to securely pack it during transportation.

Take Into Account The Type Of Sealing Equipment Utilized

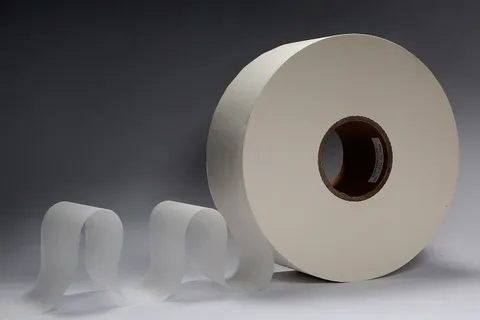

The machine that you have to use to seal your packages influences the size and shape of the paper you are required to choose. There are sealing machines that use a paper roll, and also those that are more suitable for the cut-sheet. Custom Heat Seal Paper Roll provides the advantage of accommodating a variety of sizes of products and may necessitate more careful cutting. Conversely, the Heat Seal Paper Sheets offer predictable sizing and minimize wastage, although they can inhibit flexibility. Specification of your equipment will save time and wastage of materials.

The Bulk of Materials Counts

It is also essential that you pick the proper thickness of your heat seal paper, which is just as important as its size. Weightier ones protect more, perhaps necessitating a larger size in order to fit the greater bulk of paper itself. Lighter sheets, like Glassine Paper Sheets, can have smooth surfaces and can be many times less protective. Strike a balance between the protection requirements of your product and efficiency, which may result in the best thickness and size.

Personalize Your Paper to Brand and Utilize

Some of the benefits of ordering Custom Heat Seal Paper are that you can “get paper custom designed not only in size but also design”. This increases your brand’s presence nd at the same time, gives it a good fit. Personal dimensions avoid wastage of supplies and look good and professional. You can consider dealing with companies that make custom sets of packaging, which will be able to aid you in choosing sizes that suit your product and equipment best, and still include your branding.

Your Paper Size Selection Depends On Bulk Purchasing Possibilities

In case you already use heat seal paper, it is possible to save on prices by purchasing the necessary quantity in one order through Heat Seal Paper Wholesale suppliers. It is, however, desirable that you select a size that is also flexible to use in case you have a variety of product lines that you need to use in your business. The sizes of bulk must be sensible to your most frequent product sizes to save as much as possible and reduce waste as much as possible. You should think about your size requirements ahead of time, so your ordering process will be very smooth.

Exactness Between Size And Waste Reduction

Selecting a bad size may either end up in the wastage of a lot of paper or sealing failure. The size that is too large implies that there is a need to be trimmed and wasted, but on the other hand, that which is too small may not seal completely or break. When the size is important- Custom Printed Heat Seal Paper, the use of Custom Printed Heat Seal Paper will make it precise in lengths and widths, and waste material consumption would also be reduced. You can have custom sizes to fit your product, and this will lessen environmental catastrophe and keep down expenses.

Find the Various Ways in Which You Can Do Your Packaging

Heat seal paper is available in many formats, such as Heat Seal Paper Bag and pre-cut meat trays or rolls. Bags are time savers and give the same size, but may not suit all products. The rolls are flexible and need more cutting equipment. Having an idea of the advantages and disadvantages of each format is going to assist you in identifying the best package size and shape in the packaging workflow.

The Quality and Durability are Not to be Sacrificed

The quality of the heat seal paper is also of great importance, even with the correct size. Poor materials may result in low seals, contamination, or spoilage of the products. Choose the supplier who offers high-quality paper like Custom Printed glassine paper, which will be durable without losing its size accuracy. Quality and perfect sizing ensure customer satisfaction of the customers and help in minimizing returns or complaints.

Conclusion

Selecting the size of your personalized heat seal paper is a mix of both comprehending your requirements of the products you are packing, how you see it, and what you are packing it into. It involves meticulous measurement, planning of materials, and in mo, st cases te teaming up with other successful manufacturers in getting the results as outstanding as possible. Regardless of choosing sheet rolls, st, and bags, they should concentrate on accurate sizing, which will minimize the wastage, enhance the performance in terms of product protection, and enhance your product presentation. When you take time to choose the right size of heat seal paper, you guarantee yourself efficiency, economy, and a high level of packaging that satisfies your business needs.